CONSTRUCTION SAFETY NETS

Construction Safety Nets

Introduction

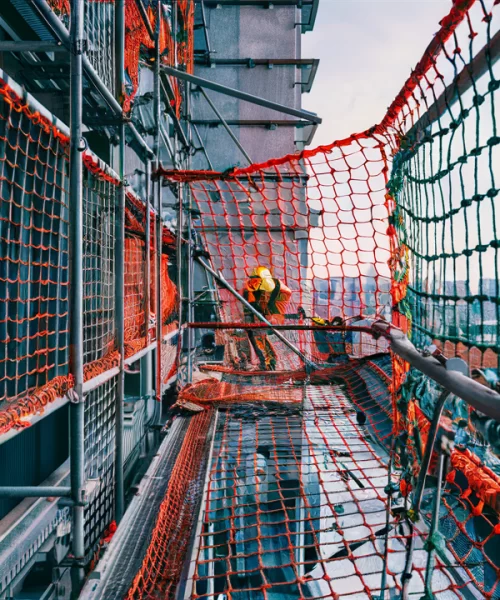

Construction sites are bustling with activity, often involving heights, heavy machinery, and numerous hazards. Ensuring safety in such environments is paramount. One essential safety measure is the use of construction safety nets. These nets are designed to protect workers and pedestrians from accidents and falling debris, making construction sites safer for everyone involved.

What Are Construction Safety Nets?

Definition and Purpose

Construction safety nets are specialized nets installed around construction sites to catch falling workers or debris. Their primary purpose is to prevent injuries and fatalities by providing a protective barrier.

Key Components

A typical construction safety net system includes the net itself, anchorage points, connectors, and supporting structures. These components work together to create a robust safety mechanism.

Types of Construction Safety Nets

Horizontal Safety Nets

Horizontal safety nets are installed below working platforms to catch falling objects and workers. They are commonly used in high-rise buildings and bridge construction.

Vertical Safety Nets

These nets are positioned vertically to protect workers from falls when working on scaffolds or near the edges of structures. They also prevent debris from falling outside the construction site.

Debris Nets

Debris nets are designed specifically to catch falling construction materials, preventing them from reaching the ground and posing a risk to people below.

Personnel Safety Nets

These nets are tailored to catch workers who may fall from heights, ensuring they are safely suspended until rescued.

Materials Used in Construction Safety Nets

Polypropylene

Polypropylene is a popular material for safety nets due to its strength, flexibility, and resistance to weather conditions.

Nylon

Nylon nets are known for their durability and high tensile strength, making them suitable for heavy-duty applications.

Steel Wire

Steel wire nets offer maximum strength and durability, often used in situations where heavy loads or extreme conditions are anticipated.

Installation of Construction Safety Nets

Pre-Installation Planning

Proper planning is crucial for effective safety net installation. This involves assessing the site, determining the net type and size, and planning the anchorage points.

Proper Techniques

Safety nets should be installed according to manufacturer guidelines and industry standards to ensure they provide adequate protection.

Common Mistakes to Avoid

Avoiding mistakes such as improper anchorage, using damaged nets, or incorrect installation angles can prevent failures and ensure optimal safety.

Regulations and Standards

OSHA Standards

The Occupational Safety and Health Administration (OSHA) sets stringent standards for the use of safety nets in construction, focusing on installation, maintenance, and inspection.

EN Standards

European Norm (EN) standards also provide guidelines for safety nets, ensuring they meet high safety and quality benchmarks.

Local Regulations

Different regions may have additional regulations that construction companies must adhere to, ensuring the safety nets comply with local safety requirements.

Benefits of Using Construction Safety Nets

Enhanced Worker Safety

Safety nets provide a reliable safety measure, significantly reducing the risk of injuries from falls.

Prevention of Falling Objects

By catching debris and tools, safety nets protect both workers and pedestrians from potential harm.

Increased Efficiency

With safety nets in place, workers can operate with greater confidence and efficiency, knowing they are protected from falls.

How to Choose the Right Construction Safety Net

Assessing Project Requirements

Consider the specific needs of your project, including the height, type of work, and potential hazards.

Considering Load Capacity

Ensure the net you choose can handle the expected load, including workers, tools, and debris.

Evaluating Durability

Look for nets made from durable materials that can withstand environmental conditions and heavy use.

Maintenance and Inspection of Safety Nets

Regular Inspection Protocols

Regular inspections are essential to ensure the nets are in good condition and functioning correctly. This includes checking for tears, frays, and other damages.

Cleaning and Storage Tips

Proper cleaning and storage extend the life of safety nets. Keep them dry and store them away from direct sunlight and chemicals.

Repair and Replacement Guidelines

Repair any minor damages immediately and replace nets that are beyond repair to maintain safety standards.

Common Challenges and Solutions

Weather Conditions

Extreme weather can affect the performance of safety nets. Choose weather-resistant materials and inspect nets more frequently during adverse conditions.

Installation in Difficult Areas

For complex areas, consider using custom-shaped nets and advanced anchorage techniques to ensure full coverage.

Budget Constraints

While high-quality nets may be more expensive, investing in durable and reliable safety nets can save money in the long run by preventing accidents and delays.